A well system is a crucial part of many homes, providing fresh water directly from underground sources. However, many well owners face challenges like low water pressure, contaminated water, or sputtering faucets. These issues are often caused by not understanding the well’s anatomy and how its components work together. By understanding the anatomy of their well, homeowners can make informed decisions and recognize potential problems like low water pressure. Well Manager provides solutions that ensure consistent water flow, even in low-yield wells, making water access reliable year-round.

Anatomy of a Well: How Each Part Works

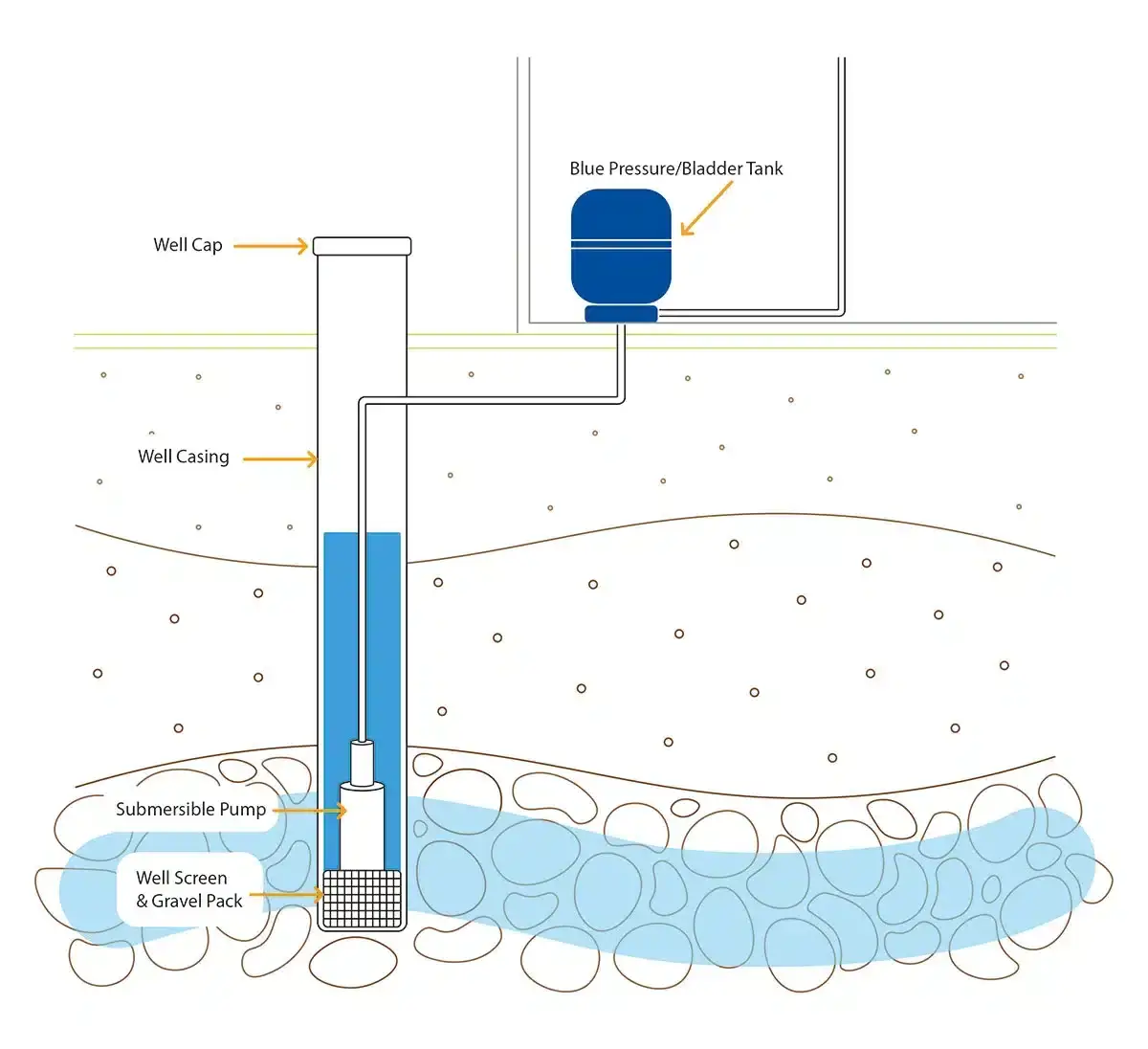

A well is a carefully designed system composed of multiple parts that must function together to deliver clean and reliable water. Below are the key components and how each affects your water supply.

- Well Cap:The well cap seals the top of the well, preventing debris, insects, and other contaminants from entering the system. It’s essential to keep the water supply clean and avoid issues that compromise water quality.

- Well Casing:The well casing is a tube that lines the inside of the well, protecting the well’s structure and keeping groundwater contaminants from seeping into the system. The casing also ensures the well’s walls do not collapse, allowing for uninterrupted water flow.

- Well Screen and Gravel Pack:At the base of the well, the well screen filters out large particles and debris, while the gravel pack provides an additional filtration layer. These components ensure that only clean water is drawn into the pump, preventing clogs that can reduce water pressure.

- Submersible Pump:The submersible pump is located at the bottom of the well, and draws water from the aquifer and delivers it to your home. The pump’s performance is crucial in maintaining adequate water pressure. If the pump is undersized or improperly placed, it can cause low water pressure.

- Pressure Tank:The pressure tank helps regulate water pressure within your home. It stores water and ensures a steady flow while preventing the well pump from overworking. If the pressure tank is malfunctioning or undersized, you may experience inconsistent water pressure throughout your home.

These components form the backbone of your well system. Problems such as low water pressure or contamination can arise when any part malfunctions or is improperly designed.

Well Water Problems and How We Solve Them

Many well systems struggle with low water pressure, especially during drought or when the well is a low-yield system. Common well problems include:

- Low Water Pressure:This occurs when the well doesn’t produce enough water to meet household demands. It’s a frequent issue in low-yield wells or when the submersible pump is not functioning optimally.

- Sputtering Faucets:Air in the water line or a malfunctioning pump can cause faucets to sputter, disrupting water flow and indicating that the system isn’t working efficiently.

- Contaminated Water:If the well cap is damaged or the well screen is clogged, contaminants can enter the water supply, leading to reduced water quality and health risks.

These issues are often signs that the well is not functioning properly. Wells that deliver water at a slower rate than necessary are known as low-yield wells, making daily tasks—such as showering or running household appliances—difficult.

How Well Manager Solves Low-Yield Well Problems

At Well Manager, we specialize in solutions designed to combat the challenges of low-yield wells and water pressure. Our systems provide homeowners with consistent, reliable water access, even during drought or high usage.

A Well Manager system ensures that your well can supply a steady flow of water, even if your well struggles to keep up with demand. Our solutions work by:

- Increasing Water Pressure:With a water pressure booster or our advanced water storage systems, Well Manager improves the pressure within your home, ensuring that water flows consistently without pressure drops.

- Preventing Overpumping:Overpumping can damage the well and cause contamination. Our systems monitor and regulate water use, preventing the pump from running dry and protecting your well from overuse.

- Protecting Equipment:Well Manager systems prevent pumping equipment from running dry, which can lead to wear and tear. This helps extend the life of your well pump and other components.

Our products can handle the unique challenges of low-yield wells. Established in 2017, Well Manager was born in the Sourland Mountain region of New Jersey, where low-yield wells are common. With years of experience dealing with inadequate water sources, we’ve developed solutions that boost water pressure and protect your well from damage caused by overpumping or sediment buildup.

Protect Your Well and Guarantee Steady Water Pressure

Understanding the anatomy of your well is critical for maintaining a reliable water supply. Each component ensures that your well delivers clean, consistent water from the well cap to the pressure tank. When problems arise—such as low water pressure or contaminated water—the Well Manager is here to provide the solutions you need. Whether dealing with a low-yield well or struggling with sputtering faucets, our systems maintain water pressure and ensure a steady supply.

Investing in a Well Manager system can protect your well, increase water pressure, and enjoy consistent water flow, no matter the challenges your well faces.

Related Reading

- Well Manager Timed Water Collection System for Low-Yield, Low-Water Pressure Problems

- Why Drilling Deeper Wells Does Not Solve Low-Water, Low-Pressure Wells

- What Do I Need to Ensure My Summer Camp Can Efficiently and Reliably Run on Well Water?

- Top Reasons to Avoid Manually Adjusting Pressure on a Well Pump

- Why a Booster Pump Alone Often Isn’t Enough to Meet Residential Well Water Demands